PE Potable Water Pipe Systems

Today, 95% of the pipes used in natural gas, potable water, and sewer systems in developed countries are plastic-based.Due to the high cost of materials and installation,longer service life, and fewer maintenance issues, plastic pipe systems are rapidly replacing traditional metal ones. Studies show that in a 1 km pipeline, the likelihood of damage in metal systems is more than twice that of plastic systems.

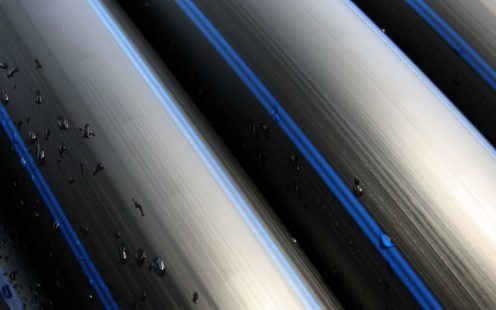

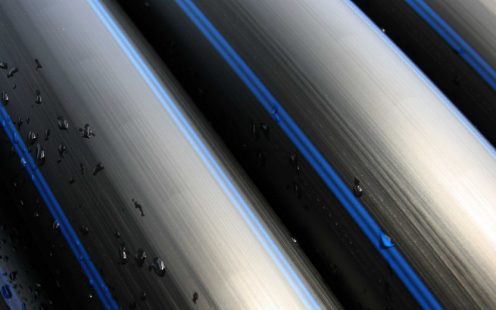

Flexible PE Pipes

In addition to High-Density Polyethylene (HDPE) pipes, ARILI/PIPELIFE also produces Low-Density Polyethylene (LDPE) pipes with circular winding. Commonly known as flexible polyethylene pipes, these products are manufactured in accordance with TS 418/2 Turkish Standards, as well as DIN 8072, DIN 8073, and prEN 12201 standards.

Applications of Low-Density Polyethylene (LDPE) Pipes

- Potable water lines

- Agricultural irrigation systems and greenhouses

- Chemical transportation systems

- Advantages of Low-Density Polyethylene (LDPE) Coil Pipes

- Since Low-Density Polyethylene (LDPE) pipes are softer than High-Density Polyethylene (HDPE) pipes, they can be installed more easily within channels and in narrower working areas. Thanks to their lower installation costs compared to straight pipes, the use of coil pipes is becoming increasingly common both in Turkey and worldwide.

- Depending on the required pipe diameter, they can be produced in lengths of 50, 100, or 150 meters, allowing longer distances to be installed seamlessly and in a shorter time with fewer fittings.

- Due to their flexibility and length, the pipes can be inserted through existing asbestos cement, cast iron, PVC, or steel pipelines, allowing renovation of old or damaged lines without the need for trench excavation.

- They are used for crossings under seas, lakes, and rivers without the need for additional joints.

- Since fewer joints are required for connecting the pipes, local pressure losses are significantly reduced.

In the production of Low-Density Polyethylene (LDPE) pipes, PIPELIFE uses PE 32 grade raw material (with a minimum required strength of MRS = 3.2 MPa). The pipes are typically manufactured from black raw material and contain 2.5% well-dispersed carbon black, providing excellent protection against sunlight (UV radiation).

PIPELIFE’s flexible PE coil pipes are approved by the Ministry of Health as safe for contact with potable water.

Rigid PE Pipes

In addition to Low-Density Polyethylene (LDPE) coil pipes, ARILI/PIPELIFE also produces High-Density Polyethylene (HDPE) pipes to meet the needs of public and private institutions for potable water and sewer systems.

Widely used worldwide in water supply and sewerage applications, HDPE pipes are manufactured in compliance with TS 418, ISO 4427, prEN 12202, and other relevant standards.

In the production of PIPELIFE HDPE water pipes, high-quality raw materials are combined with modern, computer-controlled technology and equipment to ensure superior performance.

Depending on customer requirements, PIPELIFE HDPE pipes are produced using PE 80 and PE 100 grades and can be supplied in straight lengths or, for diameters up to Ø125 mm, in coils. For coiled pipes, the minimum coil diameter must be at least 20 times the pipe diameter.

Raw Material of Polyethylene Pipes

ARILI/PIPELIFE uses certified, high-quality raw materials produced by globally recognized manufacturers in the production of polyethylene pipes.

The High-Density PE 100 grade materials, specially developed for natural gas and pressurized water pipe production, are stabilized to enhance pipe performance against the effects of ultraviolet (UV) radiation.

All PE 63, PE 80, and PE 100 grades used in potable water pipe production comply with the relevant regulations of the European Community (EC) and the FDA, are non-toxic, and meet all required hygiene standards.

The PE 63, PE 80, and PE 100 materials used by PIPELIFE in polyethylene pipe production share the following common features:

- Very high environmental stress crack resistance (ESCR) ensuring maximum service life

- Excellent abrasion and friction resistance

- High chemical resistance

- Superior impact strength

- Outstanding wear resistance

- Excellent point loading and squeeze-off performance

- High resistance to sunlight (UV protection)

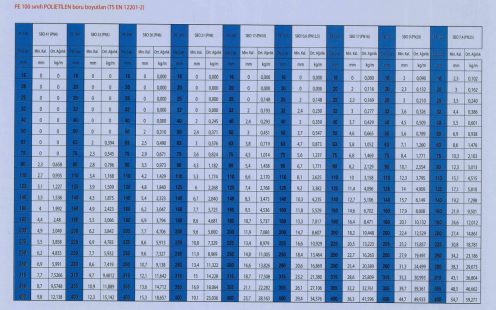

Dimensions of Polyethylene Pipes

Joining of Polyethylene Pipes

The following methods are used for joining polyethylene pipes:

A) Electrofusion Welding

This is a simple and cost-effective pipe joining method. Electrofusion welding is successfully applied for joining pipes between Ø20 mm and Ø110 mm. It also allows for creating branch connections from the main pipeline. This method is particularly used for repairs and in areas that are difficult to access.

B) Butt Welding

In this technique, the ends of the PE pipes to be joined are heated simultaneously using an electrically heated plate. The melted ends are then pressed together under controlled pressure for a specific time, creating a strong and reliable joint. This method is effectively used for pipes ranging from Ø90 mm to Ø400 mm.

When performed correctly, the strength of the welded joint is equivalent to that of the original pipe itself.

get in touch

Please select how you would like to contact us. We will get back to you as soon as possible.

Let Us Call You